The Rising Damp Myth and Condensation Problems in Air Tight Homes.

|

|

Chimneys demolished, Thousands wasted due to condensation. – Video

Is it a leak(water ingress) or Condensation.

Introduction to Damp Problems.

I don’t do Damp Surveys or investigate Damp patches around chimneys or any other Condensation problems. I would however recommend educating yourself about damp problems before drawing up a remedial work schedule. The information here is here to help you increase your awareness of conditions in badly ventilated houses with rubber sealed air tight windows.

In my experience the most common type of Damp Problem I see is “Condensation”. Which often begins with a call from someone telling me they “have a leak”, even though its “cause” doesn’t make much sense.

Buying yourself a Thermopro TP50 Indoor Temp & Humidity Meter at Amazon (for less than £20.00) Will help you improve your living space and increase awareness of the air quality in your home.

Damp Descriptions

- It’s coming in through the pointing so the pointing needs sealed.

- It’s coming through a crack in the wall so you need to seal the wall.

- I can’t see any damage so the Roof tiles or the lead needs sealed

- I need an estimate to fix what I can’t define.

The Damp Problems explanations often sound strange as they are mostly created to support a penetrating damp theory.

Often the conversation become’s difficult as the customer repeatedly tells me what’s causing theDamp Problems while asking me whats wrong at the same. “Its definitely not condensation” being a typical response.

But Lets take a step back for a moment and think. IMO Since the advent of PVC Windows

the vast majority of internal “Moisture” Problems are in fact caused by Condensation.

Trickle Vents are a very economical and increasingly common solution to many Condensation

issues. I therefore find it quite unreasonable to call a Builder out to a problem room or space

which doesn’t have trickle vents or adequate ventilation in area in question and then ask them

what the problem is.? If you require trickle vents installed I would recommend Allan Hall

There are plenty of Jane Doe’s. But the main problem is there are plenty of Building Surveyors, Agents and Builders who will agree with Jane Doe and help her perpetuate the myth by giving her a Remedial Work Schedule costing thousand’s of pounds.

Always Remember “Your House needs to breath”

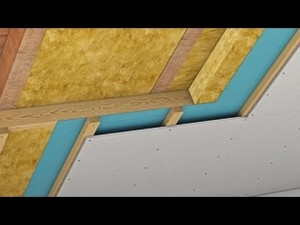

Good Insulation & Good Ventilation means Savings & Quality & Healthy Living Space

A few Myths Explained

Stephen Boniface, former chairman of the construction arm of the Royal Institution of Chartered Surveyors (RICS), has told the institute’s 40,000 members that ‘true rising damp’ is a myth and chemically injected damp-proof courses (DPC) are ‘a complete waste of money’

In response, the RICS has put the term ‘rising damp’ in inverted commas in its latest factsheet – according to Boniface, as a ‘non-subtle hint’ to its members.

‘The most likely causes of damp are moisture penetration and, most commonly, condensation,’ said Boniface in an interview with NBS Learning Channels (click here to view).

In response, Elaine Blackett-Ord, chair of the Register of Architects Accredited in Building Conservation, has also spoken out against rising damp, saying it was as rare as ‘rocking-horse shit’. Blackett-Ord said:‘’This self-perpetuating industry is believed to be worth over £200 million per year.’

But lets be clear : Were you have obvious damage or defect which corresponds to a localised internal staining etc then it must surely be penetrating moisture. The common mistake is to simply reverse engineer every problem that it “has to be ” coming from outside.

Approx £250 million per year is made on this self-perpetuating industry.

Commercial pressures.

Many “surveyors” are essentially salesmen, and some even take a percentage commission on the damp-proofing work they specify. Dont invite a damp-proofing company to inspect your home for dampness problems and be surprised if they “discover” its existence. As its how they make a living.

These salesmen use electrical conductance-type meters to “diagnose” rising damp. These are labelled “moisture meters”, but they do not really measure moisture. They measure electrical conductance, and give a reading on any building material which allows an electric current to flow through it.

Problem is Clinker blocks, for example, which are made from coal ash, have a high carbon content, which means they conduct electricity. So clinker blocks will always give a high reading on one of these meters, even when they are bone-dry.

These meters are calibrated for timber and they can give reasonable approximations of moisture contents in wood, but on bricks, plaster and wallpaper they give readings which are way too high, this means they can ea

Moisture, relative humidity & Damp Problems

Building surveyors are similar and are famous for using vague generic language when surveying houses up for sale. A house which is empty for even a few days in winter can be diagnosed to appear problematic when the house is in fact fine.

Condensation – the basics

Condensation is the most common form of damp problems in buildings, due to the introduction of double glazing, which reduced ventilation of the property. Older properties, with sash windows and open fire-places are far less likely to be as severely affected by surface condensation.

Moisture, relative humidity & Problems

Condensation is often due to ‘life-style from Cooking, Bathing and just general activities and breathing etc this coupled with a lack of ventilation can easily cause the damp problems.

Before looking at condensation it is necessary to understand a little about water vapour in the air. At any given temperature the air can hold a given level of water as vapour – the warmer the air the greater the potential amount of water vapour that can be held.

For example: Air at 10ºC is saturated when it contains 7.6g water per kg dry air and, air at 20ºC is saturated when it contains 15.3g water per kg dry air – just over double. So if we know the maximum amount of water that can be held it is very useful to know how ‘saturated’ the air actually is.

For example the proportion of actual water vapour compared to the maximum amount that can be held at a given temperature. This proportion is known as the RELATIVE HUMIDITY (rh) and is expressed as a percentage.

Relative humidity can therefore be defined as the actual amount of water vapour in the air expressed as a percentage of the maximum amount of water vapour that could be held at the same temperature.

Therefore air, say, at 10ºC could hold 8 grams of water vapour at its maximum, and if in reality only 4 grams was actually found, then the relative humidity would be 4/8 x 100 = 50% i.e., the air is 50% saturated. Similarly air at say 20ºC could hold around 14 grams of water vapour at maximum, but if we found only 7 grams in the air then the relative humidity would also be 7/14 x 100 = 50% at that temperature.

Condensation and Dew point:

What happens if we cool moisture laden air? We know that cold air cannot hold as much water as warm air. So when the air temperature has cooled so much that it can no longer hold the the same amount of water as vapor.

When this happens liquid water drops out of the air as CONDENSATION. The temperature at which condensation begins, i.e., when the relative humidity reaches 100% (air is fully saturated) is the “DEW POINT” temperature.

Surface condensation The cause of surface condensation is where moisture laden air comes into contact with a suitably cold surface – any surface including walls, floors, sub-floor areas, roof spaces, etc.

As moisture-laden air gets close to the cold surface it starts to get cooled and so the relative humidity increases; the greater it is cooled the higher the relative humidity (remember water from a large bucket passing to a small bucket as explained above). Against the cold surface the temperature of the air now drops below the dew point temperature and liquid water drops out as condensation.

Remember

1) Keep your home well ventilated by opening windows every day.

2) Always use extractors on high power when cooking and for 19 minutes “after cooking”.

3) After baths & showers keep door shut open windows with extractor fans turned on.

4) If you use a tumble dryer make sure ventilation pipe runs outside.

5) Small gaps between outside walls & furniture allows air to eventually form into black mold.

6) Air bricks and chimneys should always be clear.

7) In Winter try to maintain a constant temperature in your home.

8) Always keep the lids on pots and pans whilst cooking so that the moisture does not escape from the pans.

Damp-proofing companies exposed in Which? investigation

Where do Damp Problems come from?

Water comes from the ‘life-style’ – just normal everyday living. The amount of water produced from normal household activities can be quite considerable. Certain other activities such as using bottled gas and paraffin heaters add significant amounts of water to the air.

The by-product of burning these fuels. drying clothes over radiators etc also adds water vapour. Also consider that the surface area of your lungs is in excess of 75 square metres and warm air is passing over this wet surface as we breathe 15-20 times per minute;

This is being breathed back into the environment! Indeed, it is reported that a large dog can give off even more water vapour than the average adult! Contrary to popular belief, Damp Problems from rising/penetrating damp, and damp floors do not add significantly to the water burden in the air

because water evaporation from such ‘static’ surfaces is very low compared to breathing and other active water producing activities. Indeed, recent figures obtained from Building Research Establishment using a validated model showed that a “saturated” floor slab of 8sq.m in a room at 60% rh and 20ºC lost around 36mls water per day, ie, 5 tea spoons full!

This compares to around the 15 litres of so (nearly 4 gallons) produced from normal household activities. Indeed, and individual often produces 10 litres of water per day just form simple occupational activities. Furthermore, it becomes quite evident that given the rate of drying of a wall.

(1 month for every 25mm in thickness) then water is lost very slowly to the environment and even then most of the water passes outwards. Why? Water vapour exerts a pressure (it is part of the atmospheric pressure) and over most of the year there is more water vapour in a building that externally.

In an unoccupied property external water vapour will balance with internal water vapour, but as soon as the building becomes occupied water vapour is generated internally and adds to the environmental water burden – the more water vapour, the greater the vapour pressure.

This now means that there is a greater vapour pressure internally than external and so water vapour now passes down its vapour pressure gradient, ie, from inside to outside. Thus, the most likely direct cause of surface condensation is ‘life-style’, ie, water produced by the occupants activities, coupled with insufficient ventilation.

Occasionally one can find a ‘normal’ life-style but certain areas of walls or cold spots (e.g., dense concrete lintels) are sufficient cold to allow condensate and mould growth to form. Mould growth Water vapour in the atmosphere alone causes no problems – certainly not health problems.

Indeed, constant inhalation of very dry air can. However, condensation and maintenance of high humidities does lead to mould growth. This can usually be detected frequently by the musty odour associated with damp. Where such conditions occur it is mould spores in large numbers that may cause some to experience health problems.

The most common mould associated with condensation is the ‘black spot’ mould, Aspergillus niger. However, other moulds may also develop – it depends on the substrate and conditions. For example, some moulds will readily colonise leather at relative humidities maintained around 76% whilst on brick and paint relative humidities in excess of 88% are reported required.

Green and yellow moulds may be present; some white moulds are occasionally mistaken for efflorescent salts. It should be appreciated that some black moulds may be one of the ‘toxic moulds’, the most well know being Stachybotrys chartarum.

This particular mould is black and slimy; it also requires a cellulose based substrate, i.e., paper and cardboard. So care may need to be taken when investigating the nature of mould growth.

It is the mould growth that tends to cause the most concern because not only do they produce the musty odour but also cause decorative spoiling, and also spoiling of fabric in some cases. Moulds, once germinated, require the maintenance of persistently high relative humidities, usually over 75%, but frequently much higher.

Moulds therefore have a tendency to develop in those areas where air flow is limited and the air remains damp and stagnant, e.g., corners, floor/wall junctions, etc, where we can frequently see ‘triangular’ patterns of moulds very typical of a condensation problem (photo above).moulds.

But please note that such humid conditions can arise naturally during the humid warmer summer months, but they do not persist sufficiently long enough to maintain any mould growth. The most common proven health effect associated with moulds is asthma.

However, smoking, pets and dust mites are also know trigger factors for asthma, the latter also being found in greater numbers in ‘damp’ environments. But note that the presence of mould is not distinctly synonymous with large numbers of spores in the air; it is likely that large numbers of spores/very heavy growths are necessary before health effects become noticeable in normal healthy people although some may be more susceptible than others.

Notes: There is more water vapour within a property than externally most of the year. This is simply the result of the extra water added by ‘life-style’ (see above). Don’t expect to maintain relative humidities less than 75% during periods the summer; moisture contents of the external air are such that relative humidities internally in excess of this will naturally occur.

Beware of relative humidity figures alone without knowing the temperature! It can lead to misdiagnosis! For example in a recent case the air was reported to be at 65% relative humidity. The surface of the solid floor was pronounced to be 85% relative humidity from which it was stated that the floor was damp, possibly a damp-proof membrane defect.

However, investigation showed the floor to be dry (no capillary moisture) and, as one would expect, several degrees cooler than the ambient air temperature. This would mean that the relative humidity at the floor surface was higher! Someone hadn’t considered that the relative humidity increases as the temperature falls!

Using the same principal, don’t stick a relative humidity probe into a wall as a measurement of possible dampness – the wall is likely to be colder than the internal air temperature, and the coldness will increase the relative humidity with the same amount of water vapour in the air (NB the ‘buckets’ described above)

The higher relative humidity obtained may not reflect ‘dampness’ in a wall, just the difference in temperature! You have been warned! Finally, on the use of electronic hygrometers. Some recent tests showed that for some electronic hygrometers to come into equilibrium with the surrounding environment took some considerable time.

Thus, taking the instrument out of a cold car and using it immediately in a property would certainly give VERY misleading results. The instrument MUST be allowed to come up to room temperature (or down). Some initial tests suggests that as a rule of thumb you give a minimum of 10 minutes plus 3 minutes for each degree change in temperature.

For example coming from a cold car, say 10ºC into a room at around 20ºC will take 10 + (10 x 3) = 40 minutes before one should contemplate recording data.

If you have a Damp Problem.

As I no longer do Damp Surveys I would instead recommend educating yourself about damp problems before drawing up a remedial work schedule. Its all there for you all you need is common sense.

![Chimney Repair Belfast Bangor Holywood Newtownards Builders Roofers 20141128_155052[1]](https://www.jgm-ni.com/wp-content/uploads/2014/11/20141128_1550521-300x168.jpg)